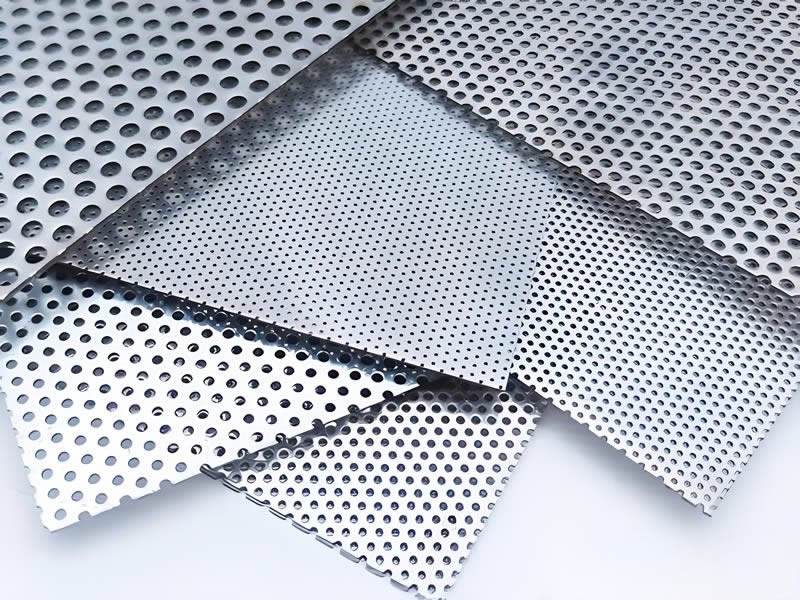

Lianxin is a trusted manufacturer of Perforated Metal, offering precision-punched sheets made from a variety of high-quality materials including stainless steel, galvanized steel, aluminum, brass, and copper. Our Perforated Metal products are manufactured using advanced CNC equipment for tight tolerances and consistent quality, suitable for both industrial and decorative purposes.

Material Options and Thickness Range

We produce Perforated Metal using mild steel, stainless steel, galvanized sheets, copper, aluminum, and nickel alloys. Sheet thickness ranges from 0.1 mm to 10 mm, with the capability to punch holes as small as the sheet thickness (e.g., 0.5 mm thick sheet can be punched with 0.5 mm diameter holes).

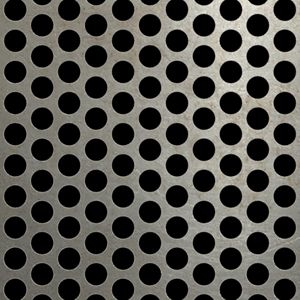

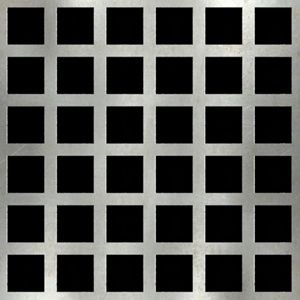

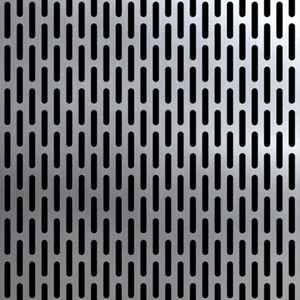

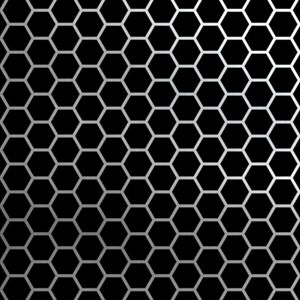

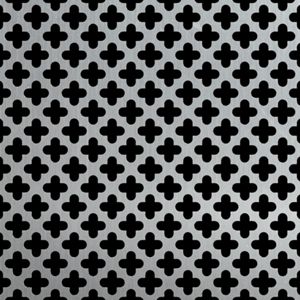

Common Hole Shapes and Patterns

Our perforation options include round, square, slotted, hexagonal, diamond, rectangular, oval, triangle, cross, plum blossom, star-shaped, and custom irregular holes. Hole sizes typically range from 0.3 mm to 100 mm, with standard practice recommending that hole diameter not exceed sheet thickness.

Standard Dimensions

- Cold Rolled Steel Sheets: Thickness 0.2 mm – 1.0 mm, Length 1 – 20 m, Hole diameter 0.8 – 10 mm

- Perforated Plates: Thickness 0.3 mm – 10 mm, Size up to 1.5 m × 3.0 m, Hole diameter 0.8 – 100 mm

Surface Treatments

To enhance durability and appearance, we offer various surface finishes such as galvanizing, painting, powder coating, polishing, anodizing, and oxidation.

Features

- High strength and durability

- Corrosion resistance

- Uniform mesh with smooth surfaces

- Easy to process and install

- Available in multiple thicknesses, pore sizes, and open area patterns

- Cost-effective for mass production and custom jobs

Applications

Perforated Metal is widely used in ventilation systems, filtration equipment, sound-absorbing panels, wall and ceiling decorations, machine guards, speaker covers, industrial screens, kitchen baskets, retail shelving, and architectural design. It is also essential in industries such as chemical processing, pharmaceuticals, food machinery, and environmental protection.

Customization

We support custom perforation patterns, dimensions, hole arrangements, and material grades according to your drawings or project requirements.